I know many of you already know about Aspen Plus or HYSYS… But I am not joking when I tell you that I get this question 1-2 times a day (via Facebook, Courses, e-mail, Contact Forms, and blog comments!) … It used to be easy and joyful to explain, but now its getting a little bit frustrating to repeat the same many times all over again. This is why I’m writing this Blog Post regarding Aspen Plus and Aspen HYSYS.

Hopefully, you get an idea of what a beauty of a tool Aspen Plus is, where it is used, why is it important and more important details.

NOTE: If you are reading this, you are most likely NEW to process modeling, if so, please check out this article FIRST.

What is Aspen Plus?

Aspen Plus (AP for short) is the leading Chemical Process Simulator in the market (or at least in the Chemical Engineering World)

AP is a software that will allow the user to build a process model and then simulate it using complex calculations (models, equations, math calculations, regressions, etc)

There are many perks in AP, from designing new processes to improving existing ones. That is so, that even AP ensures so in its website:

(it will) Maximize profits using a plant-wide simulation solution that combines unparalleled accuracy and engineering collaboration with time-saving workflows.(1)

Lets get more technical:

Given a process design and an appropriate selection of thermodynamic models, AP uses mathematical models to predict the performance of the process.

Engineers will typically simulate this using the software in order to optimize the design and improve existing ones.

This accurate modeling of thermodynamic properties is particularly important in the separation of non-ideal mixtures.

One of the best advantages is that Aspen Plus has already an existing data base of of species and their pure/binary regressed parameters.

It can also handle very complex processes, such as:

- Multiple-column separation systems

- Chemical reactors

- Distillation of chemically reactive compounds

- Electrolyte solutions such as in Chlor-Alkali Industry

- Complex Recycle – Bypass Stream in Processes

Important notes to keep in mind:

Aspen will NOT make the job for you (still not yet there.. SkyNet, here we go)

It takes an existing design that the user adds/inputs via new flowsheet or existing templates in order to simulate and improve its performance. A good process engineer will be required, as real life applications must be used while using the software. The chemical engineering principles are still required (sorry guys!)!

I personally love Aspen Plus… If you want to check out some of its features, check out this blog post.

What is Process Simulation?

Lets get something clear about Process Simulation, specially in the chemical Process Industry, is NOT drawing and modeling Equipment alone… It is mostly focused on the physical and chemical characteristic on how unit operations will work!

Process Simulation is the Art of Modeling Chemical and Physical Processes in Computer. I’m sure you have heard about the so-called “computer aided design” or CADS.

As you can imagine, long time ago there were no CADs and most calculations were done on computer or even by hand! So it is now a delight to have a CAD available for Process Simulation… If you don’t think so, I dare you to calculate the viscosity, temperature, pressure and concentration profile on ternary mix of non-ideal substances going through a Distillation Column! Case A – for 10 stages; Case B, for 20 Stages! (good luck!)

If you want to learn more on the art of process simulation, its applications, industries and so on, please check out this blog post.

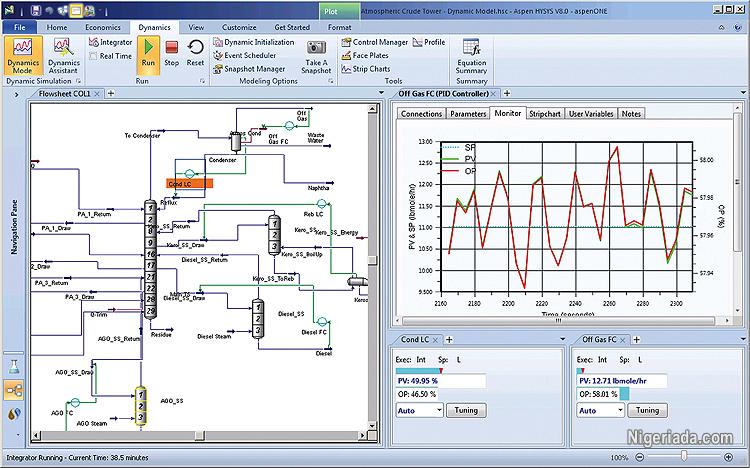

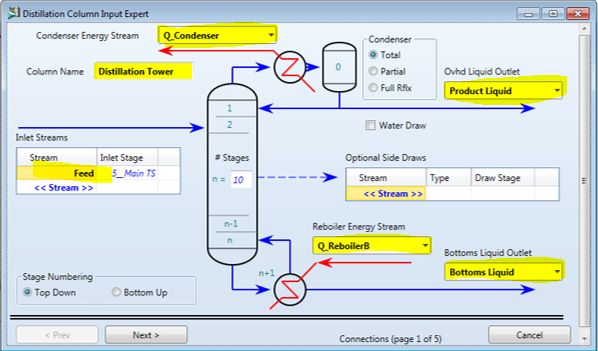

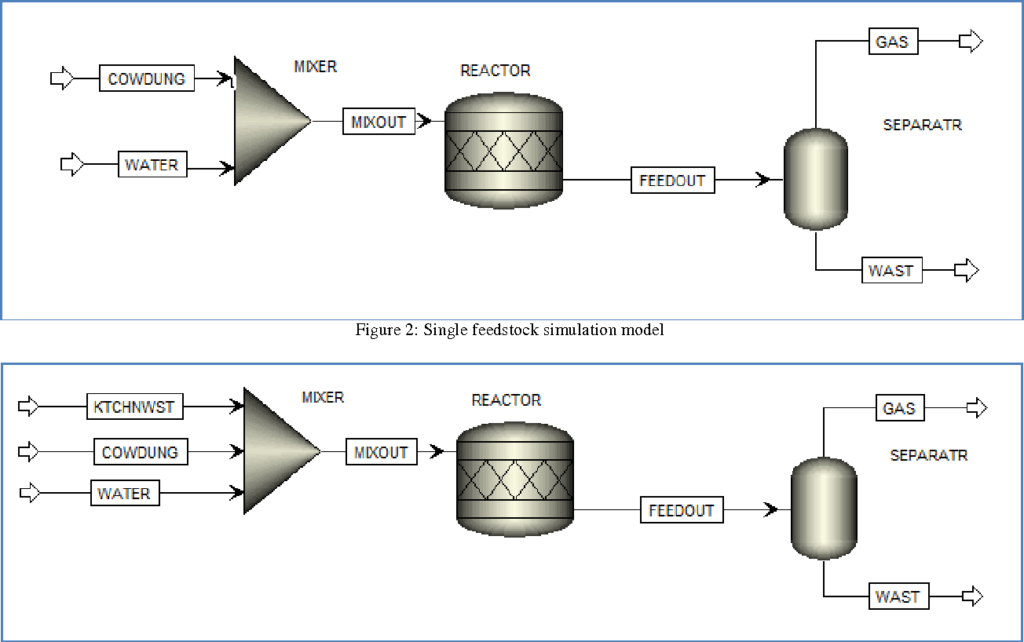

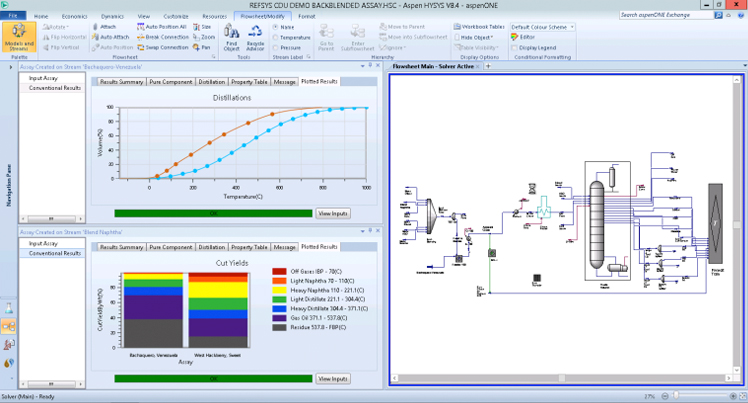

Some GUI & Screenshots

Before we continue, let’s se some VISUAL stuff regarding the simulation software so you get an idea of what we are talking about.

Note that GUI = Graphical User Interphase…

In my opinion this is one of the “best” things Aspen Plus has to offer: A very easy to use, intuitive and creative interphase in which the user can interact with the machine in order to make the simulation in the most comprehensive manner.

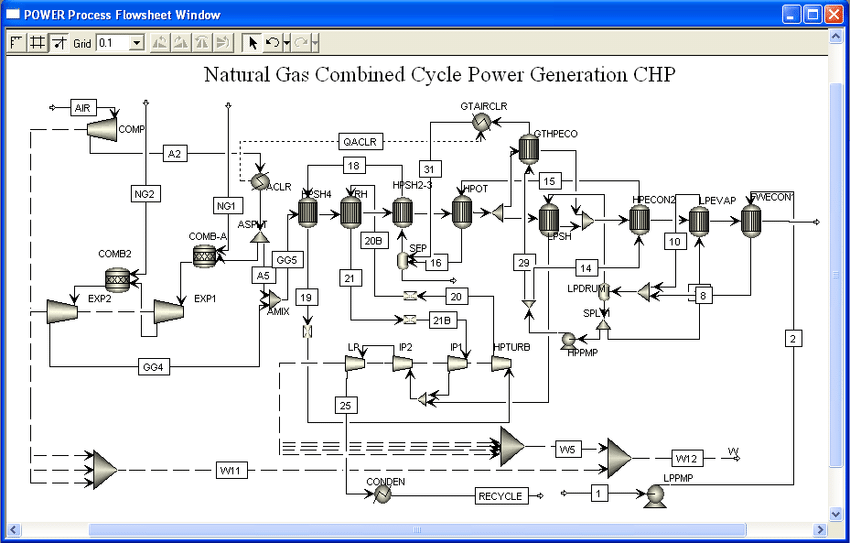

An “older” version of the flowsheet

Here you can check out the simulation environment

A little of AspenTech History

Aspen Plus is actually a product from the american company Aspen Technologies (AspenTech). You can even see their stock at NASDAQ here. As you can imagine, they are doing just great!

From wikipedia: AspenTech wasFounded in 1981. It was born out a joint research project between the Massachusetts Institute of Technology (MIT) and US Department of Energy—an Advanced System for Process Engineering (ASPEN) Project

Fun Fact: On July 15, 2004, AspenTech was required by the Federal Trade Commission to make divestitures in regard to an anti-trust ruling against its acquisition of HyproTech (they worked on HYSYS). This included divestment of batch and continuous simulation systems and integrated engineering software business (AXSYS).

Since then, AspenTech has been creating a lot of products, mostly in the following branches:

- Process Simulation for Energy

- Process Simulation for Chemicals

- Advanced Process Control,

- Manufacturing Execution Systems,

- Petroleum Supply Chain

- Supply Chain Management

- and much more…

Of these, the most relevant software that we are going to talk about are

Both of them are Process Simulation Software. If you want to read more regarding the differences between Aspen Plus and HYSYS, check it out here.

What can be modeled and simulated?

There are a lot of processes which can be modeled!

- Heat Exchanges

- Reactors

- Pressure Changers (Valves, Pumps, Compressors, etc.)

- Distillation Columns

- Absorption Columns

- Extractors

- Flash systems

- Separators & Mixers

- Solid Operations (Crushing, sieving, filtration, etc…)

- User models (unique for you!)

Actually, there are unit operations by their own (see Model Palette Below)

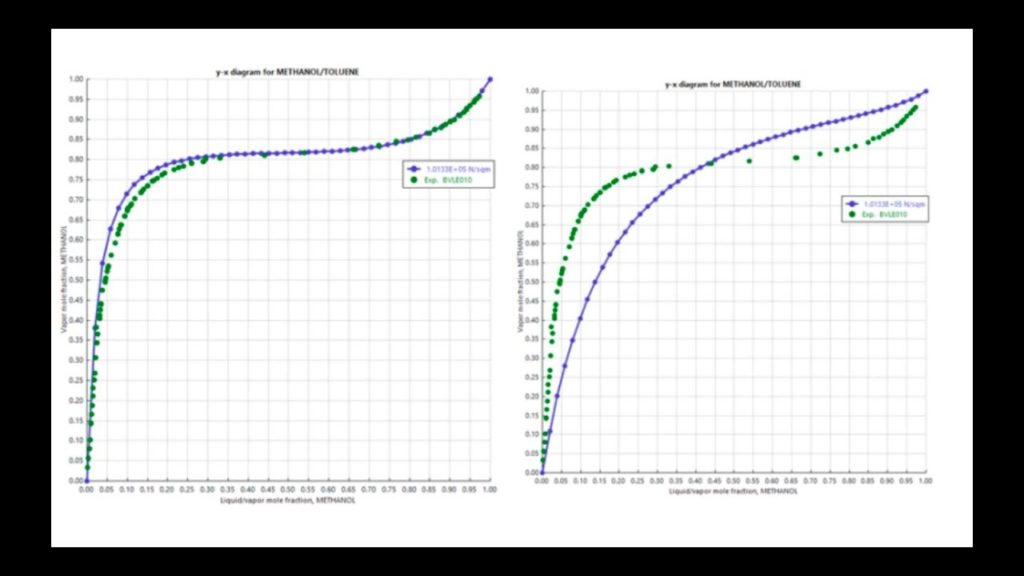

Or Physical / Chemical Properties as well: (See two diagrams below)

Or full processes with recycle and bypasses, using also User Model Unit Blocks:

Nice Tools:

- Maximize/Minimize Function: Will minimize or maximize the required variable against other using restraints(e.g. increase profit vs. cooling temperature of a chiller while considering a min. requirement of composition of a product)

- Sensitivity Analysis: will verify the “sensitivity” of a given variable against another. It can be defined by the user and graphed to verify “what if scenarios”

- Convergence & Numerical Method: Verify the number of iterations, range, errors that you are willing to work with

- Copy/Paste/Cut/Delete: this makes it easier to work with the flowsheet and it is very intuitive.

- Hierarchy levels for given process

- Run, Re-Run, Reset, Pause, Stop Simulation as you see fit

- Input data directly or indirectly by re-writing the input windows of blocks and streams

And much more! But is kinda hard to show it here, written! the more you use it the more you will get amazed (and frustrated…)

Who uses this tool?

By now you should know the importance of the software and why it is so powerful… But which companies use this software? Is your industry of interest here? Or maybe you know that at X company they use Aspen Plus…

Well, the most common industries are:

- Oil & Gas (upstream and downstream)

- Petroleum Refining

- Natural Gas

- Petrochemicals

- Chemical Industry

- Polymers

- Pharmaceuticals

- Painting & Coatings

- Food & Bevereages

You can check out more on the type of companies here… and some other important Industries here…

The other main question you are asking yourself is maybe: who is in charge of the simulation? what is the name of the job? And… You will most likely see the following “job positions” using Aspen Plus in their daily activities:

- Process Engineer

- Simulation Engineer

- Process Design Engineer

- Senior Engineer

- Plant Designer

- Plant Manager

If you see any post like that, ensure to apply with a CV having the required tools!

Where can you learn it?

There are many ways you can learn Process Simulation tools suchas Aspen Plus, HYSYS, Unisim, Coco simulator, DWSIM and so on… The most common way to learn Aspen Plus and/or HYSYS and their tools is via AspenTech’s Training center here.

Also, most of us learn it in university, either in our mass and energy balances, maybe in thermodynamics class, or at the end, when working with on a final project regarding plant design.

But I also know there are some guys out there that might/need to learn this by their own so that’s why prepared this blog post just for you! It goes deeper on how to learn process simulation in other alternate ways to the conventional one (via AspenTech). This is important specially if you don’t want to spend/invest that much of a money OR if you need another approach as the traditional one!

Where can I get access to it?

This is also a very common question I get because:

- Aspen Plus is the main Process Simulation tool in the market

- It is very EXPENSIVE (and many of you won’t pay for it)

Unfortunately, the cost of a single license varies from 30K to more than 100K depending on the industry and market, so its hard to get access to the software itself if you do not own it or your company.

The most common ways in which users get access to the software are mentioned here.

NOTE: Most courses will not include you Aspen Plus or HYSYS Access! Specially if it is not done via AspenTech. Ensure that you are NOT using an illegal copy or pirated one!

I hope this quick blog post helped you and answered: What is Aspen Plus?

Now you know what it is, what’s the main application, what it does, who uses it and where to learn more about it!

What are you going to do now?

Let me know in the comment section below!