Have you ever wonder how useful is Flash Distillation? May be you think it is a very simple process that is not actually used in the industry, or maybe you think it is just a simple unit operation… well, let me tell you it is not!

Flashing systems are very common in several industries for their ability to separate vapors from liquids. They are also used to de-gas light vapors/gases from stream lines.

The Principles Behind Flashing Units

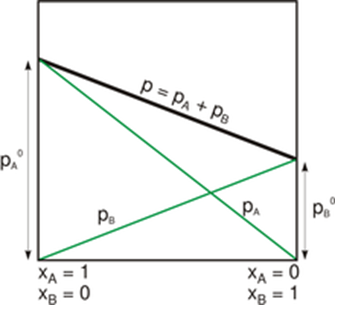

There are several physical phenomena that occurs when flashing a streamline. The most common ones are related to mass transfer. There is a relationship between partial pressure and vapor pressure which relates both phase: liquid an the vapor. When in equilibrium, they will interact between each other and distribute the components in both phases.

The main approach is to work with volatilities and K-values, yet my favorite approach to understand the basic understanding of flash systems is Raoult’s Law!

Anyways, this post is about the INDUSTRIES that use Flash Systems such as Flash Drums and so on (Note that not all flashing systems are flash drums!)

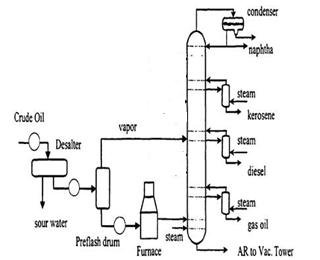

Petroleum Refining

By far, this is one of the TOP industries using flashing systems… why? because the amount of components that might be flashed will directly depend on the pressure/temperature/composition of the stream.

It is used through all the common processes of petroleum refining such as:

- Crude Oil Distillation

- Hydrotreating, Reforming, Isomerization

- Alkylation, Steam Cracking

- Fluid Catalytic Cracking

- And even Coking

This is mostly due to the appearance of hydrogen gas, high volatility alkanes and other materials such as hydrogen sulfide formation.

Check out the Oil & Gas Bundle, or the Petroleum Refining Course.

Natural Gas & LPG Gases

Yes, as you can imagine, whenever we talk about a GAS and its LIQUIFIED version, there will be some flashing… All depends on the T/P conditions and their compositions will be set.

Natural Gas can be liquified, actually the condensation point of methane, one of the lightest materials in natural gas, is about −162 °C (−259.6 °F).

Typically, we will not flash only Methane, but a mixture of light gases, some flashing systems will include Hydrogen Gas, Nitrogen Gas, Argon, Methane, Ethane, Ethyne, etc…

LPG, Liquefied Petroleum Gases will actually work much more on the flashing points as they will be more commonly be used in liquid state. It is crucial to consider the compositions of each type of LPG. As you can imagine, flashing systems are also used here to get rid of natural gas or any other component such as methanes, ethane, ethylenes, propylenes, etc.

In both cases you will see flashing systems separating liquefied products from its gases. See below example:

Petrochemical Industry

This is one of the most common examples of industries using flashing systems.

Petrochemical industry uses lots of light gases for: separation processes, mixing, reaction, product generation. Examples are the hydrogenation of species, de-alkylation, cracking, steam reforming, and so on. Most of these cases will eventually lead to some gas formation which must be flashed out of the system.

In petrochemical industries, it is very common to see “flare” systems. These are used to burn out these materials.

Here are TWO examples of a processes using Flash Drums (separating light gasses off). The left image is about Ethylene Dichloride and the right side video is Methanol production from Syngas.

If you are interested in these type or processes (petrochemicals) then check out the Oil & Gas Bundle, or the Petrochemical Industry Course.

Acid Gas Treatment (Amine Treatment)

Now, talking about Natural Gas, LPG, Petrochemical & Petroleum Refining Industries, we can’t forget the Acid Gas Treatment. It is one of the most common examples of gas treatment for sulfur removal.

As you can see from the diagram below, there is a flash drum at low pressure which will favor low molecular weight gases to vaporize.

Methane and Ethane will be recovered later on, while the stream must be further treated.

So these were some typical industries that use Flashing Systems such as Flash Drums in their processes. Now you know if studying Flashing will be useful for your professional career! SPOILER: if you work in an office, you will most likely not encounter a flash drum!

Did I missed any other one? Probably yes! Flashing is very common! Please let me know in the comments below: