Quick Guide Gas Absorbers & Scrubbers

Have you ever wondered how we ensure that the gases produced by industries don’t harm our environment? It’s not as simple as just releasing them into the atmosphere.

In fact, there are strict policies in place to prevent certain chemicals from being dispersed into the air, especially when they contribute to pollution.

On an industrial scale, we employ a range of separation processes to ensure that the gases, often referred to as off-gases, stack gases, or flue gases, are cleaned up before release.

In this blog post, we will embark on a journey into the heart of the Gas Absorption Process. But more importantly, we will demystify the inner workings of Gas Absorbers and Scrubbers, the unsung heroes of environmental protection and industrial progress.

Subscribe to My Newsletter So You Get All the Most Relevant Monthly News

Understanding Gas Absorption

Gas Absorption Defined

Gas absorption, also known as gas scrubbing, is a process used to remove harmful gases or vapors from industrial emissions or other gas streams. It is a critical component of air pollution control and is instrumental in reducing the release of harmful substances into the atmosphere.

How Gas Absorption Works

The gas absorption process involves the contact of a gas stream containing harmful components with a liquid, typically referred to as the scrubbing or absorption solution.

This liquid is carefully selected to react chemically with the target gases, transforming them into less harmful or non-toxic compounds.

The key principle behind this process is mass transfer: the gas molecules transfer from the gas phase to the liquid phase.

Types of Gas Absorption

There are various methods of gas absorption, each with its unique advantages and applications. The most common types include:

Chemical Absorption: In this method, a chemical reaction takes place between the gas and the absorption solution. The reaction products are typically water-soluble, allowing for easy separation and disposal.

2. Physical Absorption: Physical absorption relies on the solubility of gases in the absorption solution. There is no chemical reaction involved. Common absorption solvents for physical absorption include water and organic solvents.

What are Gas Scrubbers?

Gas scrubbers, often referred to as air scrubbers or pollution control scrubbers, are the devices or systems used to implement the gas absorption process. They are designed to provide the necessary contact between the gas stream and the absorption solution, facilitating the removal of pollutants from the gas.

Environmental and Industrial Applications

Gas absorption and scrubbers find applications in various industries and environmental contexts:

1. Air Pollution Control: Scrubbers are instrumental in mitigating air pollution from industrial processes, power plants, and waste incinerators.

2. Chemical Processing: They play a vital role in capturing and neutralizing hazardous gases produced during chemical reactions.

3. Semiconductor Manufacturing: Scrubbers are used to remove hazardous chemicals used in semiconductor fabrication.

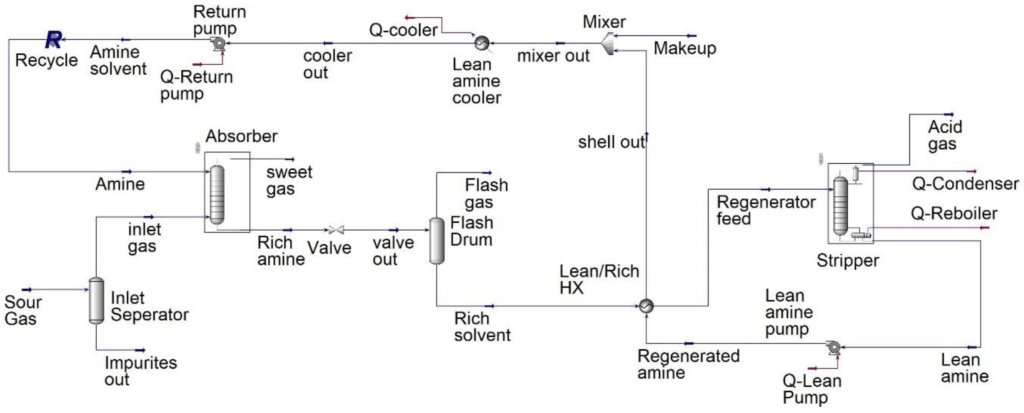

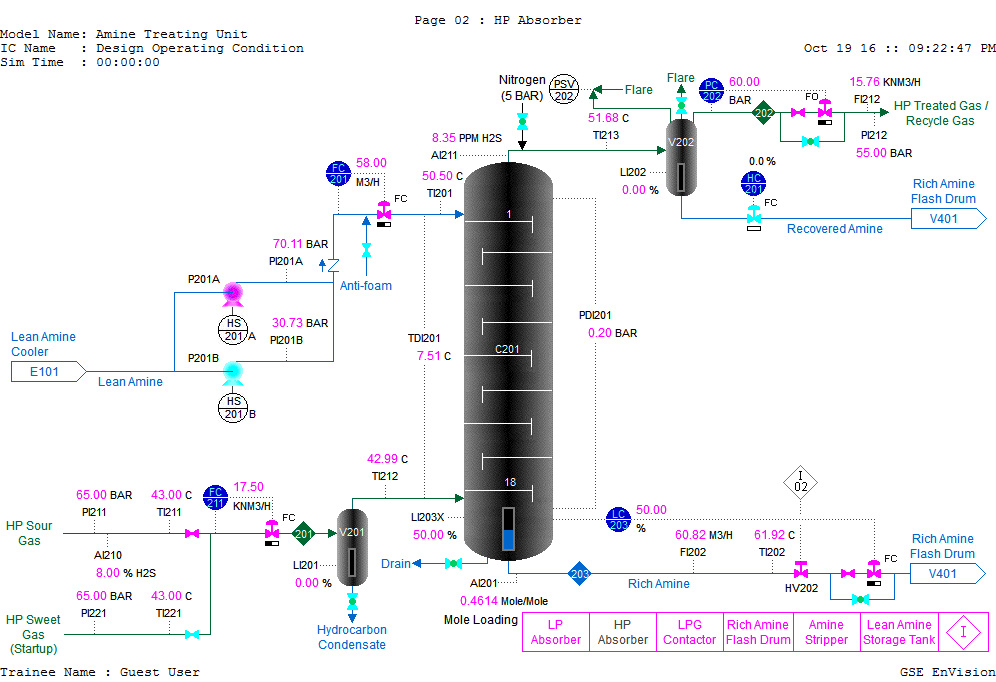

4. Oil and Gas Industry: Gas scrubbers are employed to remove harmful emissions from oil refineries and gas processing plants.

5. Greenhouse Gas Reduction: Scrubbers can also be used to capture and store carbon dioxide (CO2) emissions, contributing to climate change mitigation efforts.

Parts of an Absorption Column

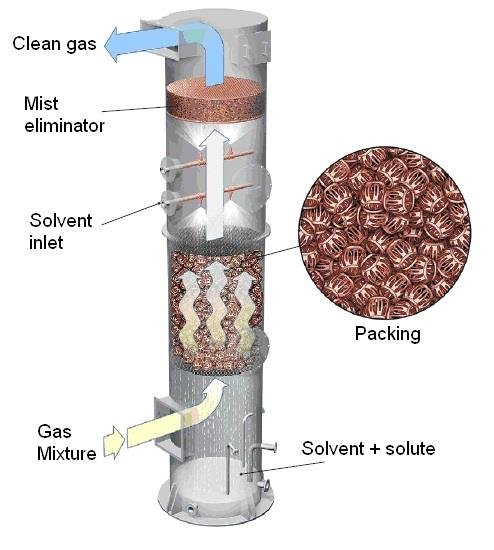

To achieve efficient gas absorption, an absorption column within the gas scrubber contains several critical parts, including:

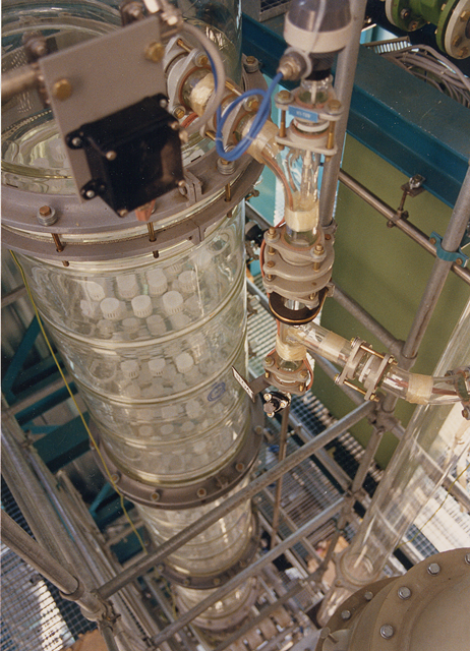

Packing Material: Depending on the design, the column may contain packing material such as structured packing or random packing. This material provides a large surface area for gas-liquid contact, enhancing mass transfer.

Liquid Distributor: Responsible for evenly distributing the absorption solution over the packing material or trays, ensuring uniform contact with the gas stream.

Trays: In trayed columns, trays are used to facilitate gas-liquid contact. They come in various designs, such as bubble cap trays and sieve trays.

Gas Distributor: In some cases, gas distributors ensure even gas distribution across the column’s cross-section, promoting efficient absorption.

Reboiler or Condenser: In some applications, absorption columns are equipped with reboilers to heat the absorption solution or condensers to cool it down, depending on the specific process requirements.

Understanding these components is crucial for optimizing gas absorption processes within the scrubber and ensuring efficient removal of pollutants.

Troubleshooting Gas Absorption and Scrubbers

Even well-designed gas absorption systems and scrubbers can encounter issues. Troubleshooting is a crucial aspect of maintaining efficient operation and compliance with environmental regulations. Common troubleshooting steps include:

Performance Monitoring: Regularly monitor the performance of the gas scrubber by measuring gas concentrations at the inlet and outlet. Any significant discrepancies can indicate issues.

Pressure Drop: An abnormal increase in pressure drop across the scrubber may suggest fouling or blockage in the packing material or other components.

Liquid Distribution: Uneven distribution of the absorption solution can lead to reduced efficiency. Ensure that the liquid distributor is functioning correctly.

Absorption Solution Quality: Check the quality and composition of the absorption solution. Contaminated or deteriorated solutions may not effectively capture gases.

Exploring the limits: Minimum Liquid to Gas Ration Required to Operate.

5. Maintenance: Regularly inspect and maintain all components, including nozzles, packing, and mist eliminators. Clean or replace components as necessary.

6. Temperature Control: For certain applications, maintaining the appropriate temperature of the absorption solution is critical. Ensure that heating or cooling systems are functioning correctly.

7. Environmental Compliance: Continuously monitor emissions to ensure compliance with environmental regulations. Address any issues promptly to avoid regulatory violations.

8. Operator Training: Properly trained operators are essential for efficient and trouble-free operation. Invest in operator training to prevent common operational errors.

Before you go...

I offer a comprehensive course that delves into the science and fundamentals of Gas Absorption & Stripping. Throughout this course, we explore a wide range of topics, including:

- Gas Absorption Phenomena

- Equilibrium Concepts

- Equilibrium Line vs. Operation Line

- Design, Operation & Troubleshooting

- Various Types of Columns

- Diverse Modes of Operation

- Components of an Absorption Column

- Comparison between Packed and Tray Columns

Final thoughts

In the realm of industry and environmental stewardship, gas absorption and scrubbers are the unsung heroes. They ensure harmful gases and pollutants don’t escape recklessly into our atmosphere, safeguarding both our environment and our health.

From grasping the basics of gas absorption to diving into the inner workings of gas scrubbers and tackling common issues, our journey has been enlightening. We’ve witnessed how these systems are pivotal across industries, from chemicals to power, aiding compliance, enhancing safety, and even bolstering energy efficiency.

As industries evolve and environmental concerns intensify, the importance of gas absorption and scrubbers cannot be overstated. They point the way to cleaner air, less pollution, and a sustainable future for generations to come.

So, as we conclude our exploration, let’s remember that by embracing these innovations and continually boosting their efficiency, we propel ourselves towards a world where clear skies and a healthier environment aren’t mere dreams but a shared reality.

Our investment in cleaner air and a better world is well worth it, and with gas absorption and scrubbers leading the way, we’re on the right track to preserve them for the benefit of all.

Is there anything in especial that you liked the most? or Maybe you are not quite into the new trends? Just reply to this e-mail and let me know!