What should you choose? What do you want to model? Which software is better for electrolytes, which one is better for petroleum? Are you going to simulate steady state plants or dynamic state? Do you want to do plenty of recycling streams or simple, straight forward process? Do your colleagues use Aspen Plus already or HYSYS?

Yeah….. plenty to answer there…

There are literally a thousand of reasons to use Aspen Plus over HYSYS, and another thousand reasons to use HYSYS over Aspen Plus.

So, what is the difference? Or which one is the most convenient?

A little bit of history...

In order to understand why are there two softwares, let us get back in time…

ASPEN PLUS

Aspen comes from the original project: Advanced System for Process Engineering (ASPEN) Project which was granted to MIT by US Department of Energy in 1981 in order to build a software able to model industrial scale chemical processes. It was later launched for private use.

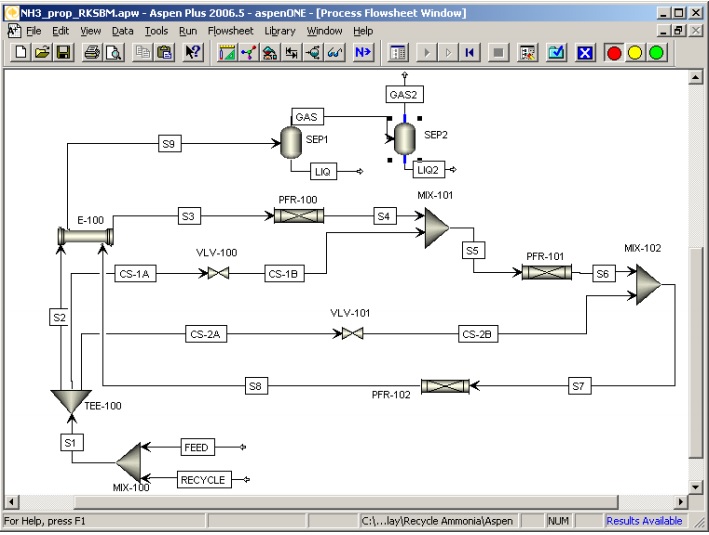

Here: Aspen Plus 2006 Version, pretty similar to what we have. GUI is not that friendly as we are used to in Aspen Plus V10.

HYSYS

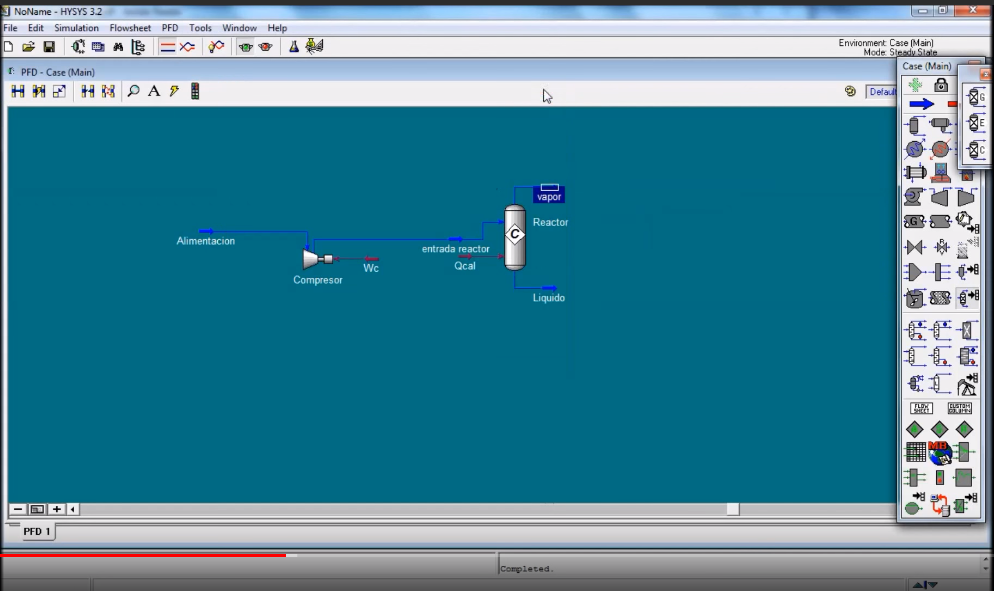

HYSYS is actually a combination of Hyprotech Systems; a copmany founded by the University of Calgary back in 1996 approx. It was originally designed to model petrochemical systems, petroleum assays and hypothetical compounds mainly. It also included a very detailed spreadsheet (green) and a tool bar with streams + blocks, pretty similar to what we have now on Aspen HYSYS V10.

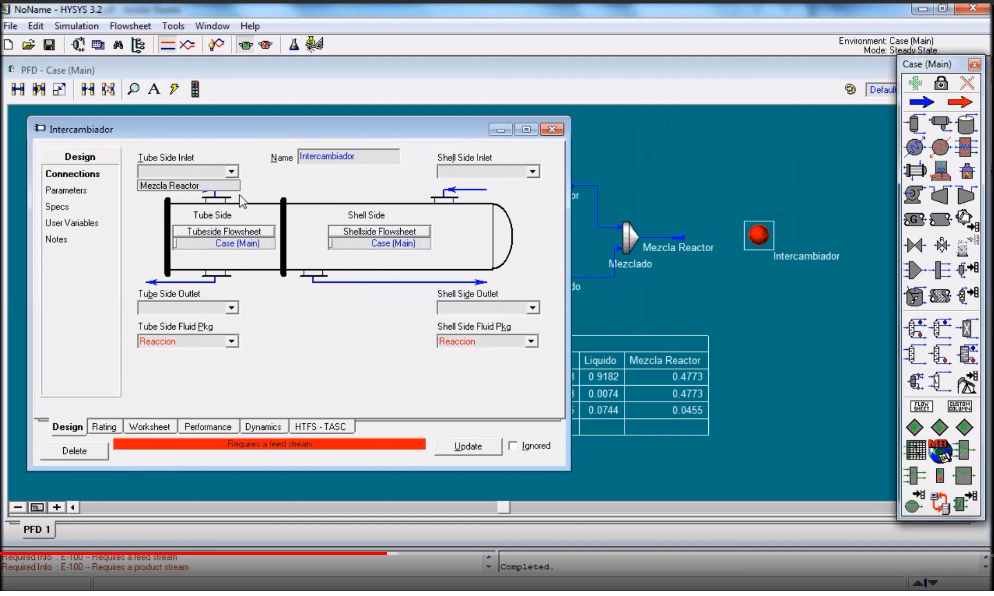

It also includes a GUI similar to Aspen Plus with respect to how we fill properties and input data of blocks:

In May 2002, AspenTech acquired Hyprotech, including HYSYS, so that’s why we have two similar softwares for process simulation.

It is important to note that 2004 ruling by the United States Federal Trade Commission, AspenTech was forced to divest in order to avoid monopoly practices. Therefore, its Hyprotech (including HYSYS source code) was sold to Honeywell.

BTW, Honeywell also got the opportunity to hire HYSYS developers; which lead to the production of the UniSim software.

Main Differences...

Ok so there are of course many differences, so lets check the most relevant ones…

This is not only technical, I checked for other fellow engineers opinions on what is the main difference between each other.

The GUI (Graphical User Interphase)

As in any software, the graphical user interphase (the visual stuff, buttons, structure, folders, overall organization, etc…) is one of the most vital parts! If you do not believe me, then try simulating a fractional column using lines codes!

In my opinion, the GUI of both softwares are pretty similar, and actually I have noted that they are looking each time more equal, as there is a theory that they will eventually be a SINGLE Aspen Tech Software.

Both have the physical & simulation environments.

There are small differences in the GUI such as how adding streams directly in the input of unit operations (HYSYS) vs. doing it later in (PLUS)

- HYSYS is supposed to be more user friendly (allegedly) but it is actually dependant on personal taste, I actually prefer Aspen Plus!

- Typically, HYSYS will be in “run” or “Active” mode, meaning that the simulation is ran every time we change something.

- Aspen Plus will not be ran until we click in the “N” or “Run” button.

Type of Simulation (Equation Oriented)

Tear Streams! yeaaah! The most taunting thing to do in Aspen Plus and is a pain in the A$$!

Thankfully, Aspen Plus allows EO (Equation oriented) Methods which favor the convergence of simulations, specially when there are plenty recycle streams.

HYSYS has the advantage of having blocks for recycling, though will not be always be enough to facilitate the convergence of the whole process

Type of Industry

This is the most common thing I have seen as a main topic of discussion of HYSYS & PLUS.

HYSYS: Petrochemical + Petroleum Refining, Oil Assays and all related Industry

PLUS: fine chemistry, general chemistry, electrolytes, polymers, etc…

Then, simply base your software of choice based on the industry

Going to model petroleum assays? use HYSYS

Going to model polymer reactivity? use PLUS

What do your colleagues use?

Yeah… many times we do not even have opportunity to choose. You just show up to work, and they will tell you which software to use.

If they have been using HYSYS for the last 5 years, then HYSYS will be!

I used to work at a petrochemical company, we modeled isopentane, cyclopentane separation from Naphtha. And we used mostly PLUS!

Pricing... $$$!

Even though they are similar in price, they might change depending on your specific needs and, more importantly, depending on what you are going to be using the most and what type of support you need the most.

As a rule of thumb, generic/bulk processes will require a more expensive license whereas niche applications will not.

Downstream & Upstream Industry

Again, if you are going to be working in the oil & gas industry, mostly oil and natural gas, then use HYSYS. This is shown to be the best software for this. Not only because it was intended to, but also because there is plenty of material online for reference!

Logical Operator Blocks

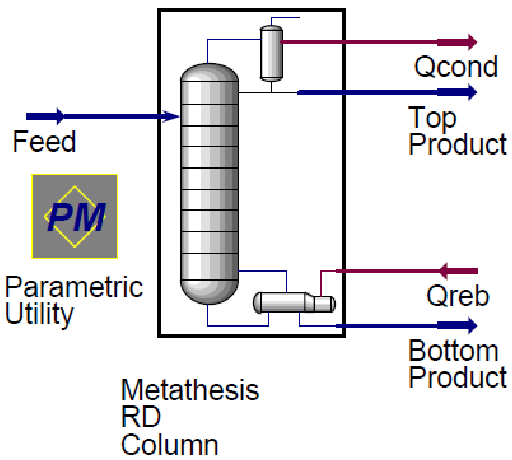

Sometimes you will have a process which involves a specific set of Logical Operations. Both of HYSYS & PLUS will have this, but depending on your specific need you might end up selecting HYSYS (recycling streams) or PLUS (FORTRAN coding)

PM Block –>

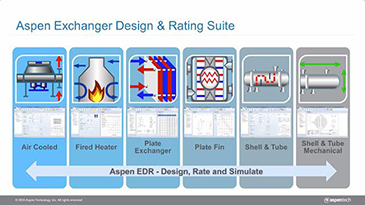

Further Plugins (Addons)

If you are going to be using more plugins (or extra applications form Aspen Tech) then you should base your decision on which you want specifically. Some of them are more reliable using Aspen Plus or HYSYS. For example, the petroleum refinery license will be better integrated directly in HYSYS whereas the polymer extension or electrolyte models will be better suited in Aspen Plus.

Wrap up!

Those were some main difference of Aspen Plus & HYSYS. You should definetively check out what is the BEST fit for your products, process and industry.

Even though it is hard to get used to several softwares, HYSYS & PLUS are actually pretty similar so don’t get frustrated if you have to change from time to time!