Quick Overview of Fluid Catalytic Crackers

When it comes to the world of petroleum refining, Fluid Catalytic Crackers (FCCs) stand as the unsung heroes, efficiently transforming heavy crude oil into valuable products like gasoline and diesel.

In this quick guide, we’ll delve into the fascinating world of FCCs, covering everything from their functions and components to operation, troubleshooting, and the environmental implications.

Subscribe to My Newsletter So You Get All the Most Relevant Monthly News

1. Understanding Fluid Catalytic Cracking

More on FCC:

Fluid Catalytic Cracking is a fundamental process in the refining industry. It represents a method of breaking down large hydrocarbon molecules found in crude oil into smaller, more valuable products.

This cracking process is vital for producing high-demand fuels such as gasoline, diesel, and jet fuel.

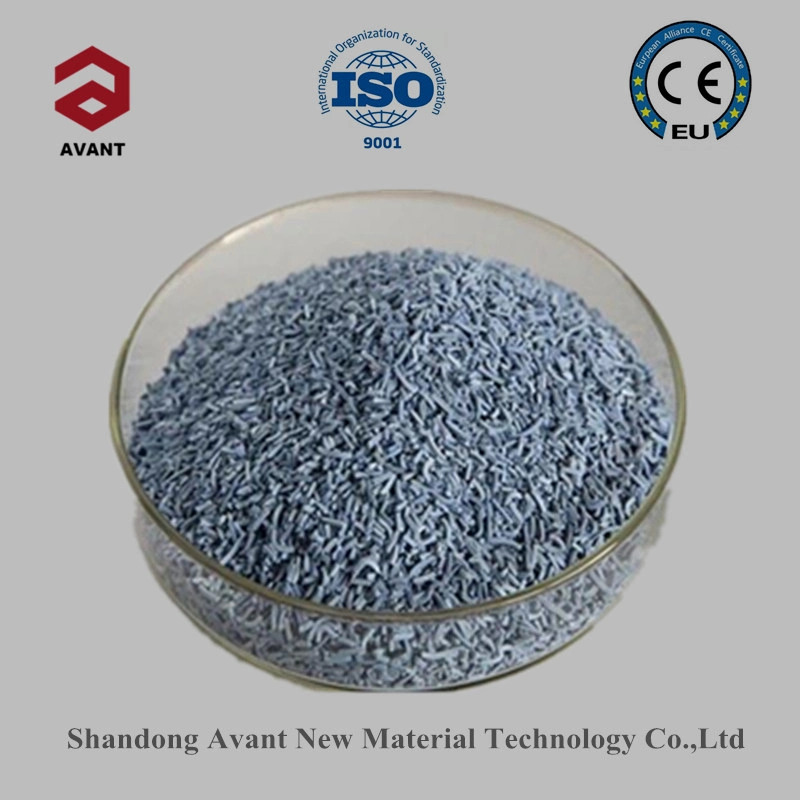

The essence of this process lies in the use of a solid catalyst, which initiates chemical reactions that result in the cleavage of hydrocarbon bonds.

The FCC process is known for its ability to efficiently convert heavy hydrocarbons into lighter, more valuable products, which are crucial for meeting the energy needs of today’s world.

This liquid is carefully selected to react chemically with the target gases, transforming them into less harmful or non-toxic compounds.

The key principle behind this process is mass transfer: the gas molecules transfer from the gas phase to the liquid phase.

FCC Explained

In this video, I cover the basics of FCC: General Description, Operation, Advantages and Disadvantages, Catalysts and more.

2. Types of Cracking Processes Used in Refining

While FCC is a prominent cracking process, it’s not the only one.

In refining, there are various cracking methods, including:

Thermal Cracking, Hydrocracking, and Visbreaking.

Each of these processes has its own unique applications, but FCC is particularly favored for its versatility and efficiency in producing a wide range of valuable fuels.

3. What Are Fluid Catalytic Crackers?

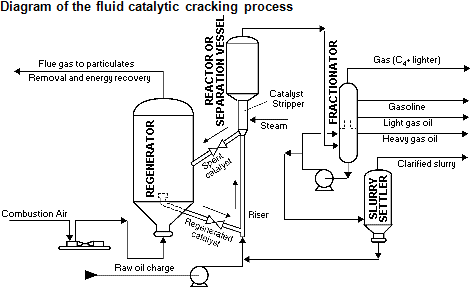

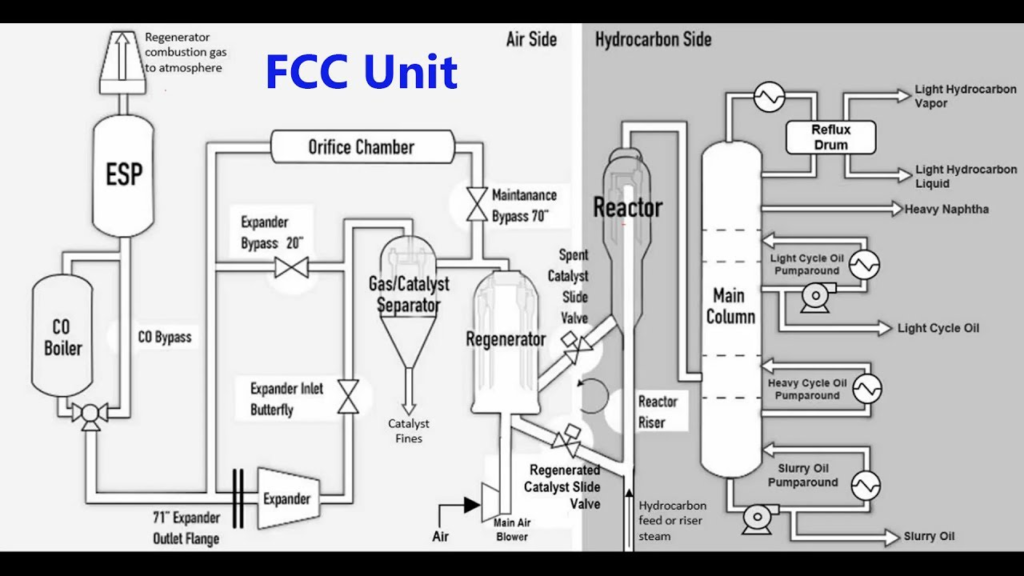

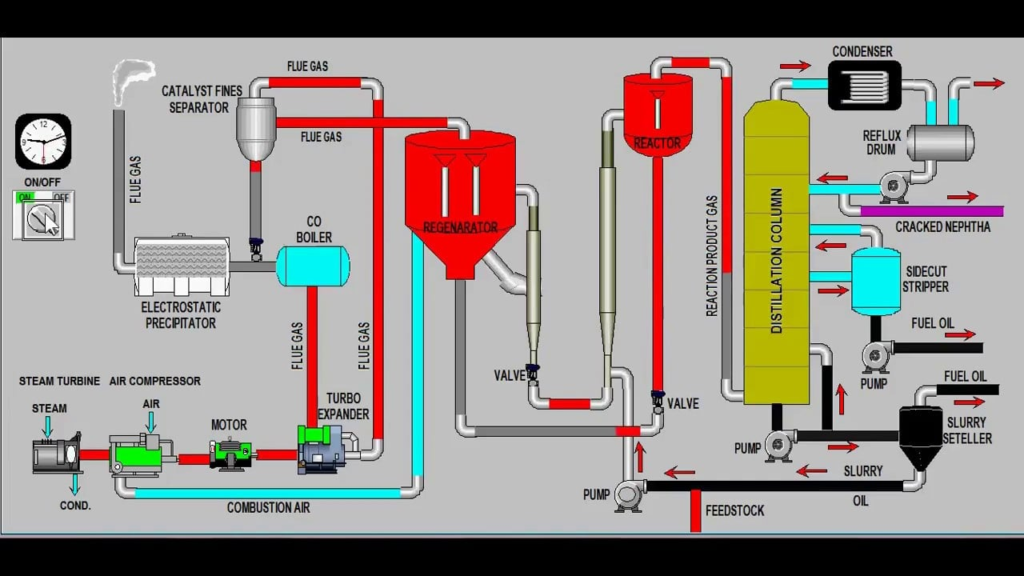

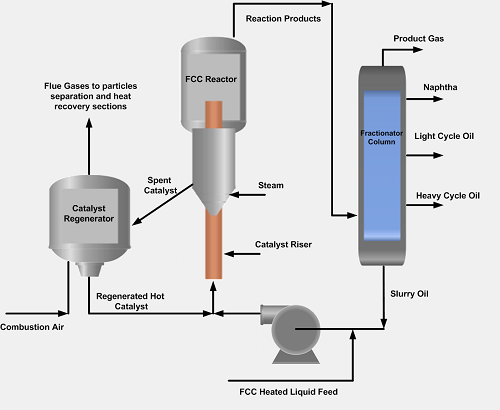

Fluid Catalytic Crackers are intricate units within refineries that encompass reactors, regenerators, and a network of catalysts. In the FCC process, solid catalyst particles are suspended in a fluidized bed and interact with feedstock hydrocarbons, facilitating the cracking reactions.

Key Components:

a. Reactor: This is where the feedstock mixes with catalysts to undergo the cracking process. The reactor is designed to provide the ideal conditions for catalytic cracking.

b. Regenerator: Once the catalysts in the reactor become spent, they are transported to the regenerator, where they are stripped of coke and rejuvenated for reuse.

c. Catalyst Handling System: This system is responsible for managing the circulation of catalyst particles between the reactor and regenerator, ensuring a continuous and efficient process.

4. How to Operate an FCC Unit

Operating an FCC unit is a complex task that demands precise control of various factors, including temperature, pressure, and catalyst-to-oil ratio. Catalyst management is a critical aspect, and its circulation must be closely monitored. Managing the severity of cracking reactions is key to optimizing product yields.

Continuous monitoring and maintenance are essential for smooth operation. Operators need to strike a balance between maximizing product output and maintaining the integrity of the FCC unit.

5. Common Troubleshooting of FCC

Troubleshooting is an inevitable part of operating FCC units. Here are some common issues and potential solutions:

a. Catalyst Deactivation:

- Issue: Over time, catalysts lose their activity, leading to reduced cracking efficiency.

- Solution: Periodic regeneration of catalysts in the regenerator to restore their activity and effectiveness.

b. Catalyst Poisoning:

- Issue: Contaminants in the feedstock, such as metals or sulfur compounds, can poison the catalyst, decreasing its performance.

- Solution: Implementing desulfurization processes and feedstock pre-treatment to reduce contaminants.

c. Reactor Fouling:

- Issue: Accumulation of coke deposits on reactor internals can disrupt flow and heat transfer.

- Solution: Regular cleaning and maintenance to remove coke deposits and optimize heat transfer surfaces.

d. Erosion and Corrosion:

- Issue: High-velocity flows and corrosive feedstocks can lead to erosion and corrosion of equipment.

- Solution: Using erosion-resistant materials and implementing corrosion prevention measures.

6. Environmental Issues

While FCC units are indispensable in refining, they also pose environmental challenges. Emissions of greenhouse gases, such as CO2 and NOx, are a concern for the industry. To combat this, refineries are continuously working on cleaner processes and technologies. Some strategies include the development of advanced catalysts that reduce emissions and carbon capture technologies.

Furthermore, the integration of renewable feedstocks, such as bio-oils, into FCC units is gaining momentum. This not only reduces the environmental footprint but also aligns with the growing demand for sustainable and eco-friendly products.

7. Future Trends for Fluid Catalytic Cracking

As the refining industry evolves to meet stricter environmental regulations and the increasing demand for cleaner fuels, FCC technology is not left behind. The future trends in FCC include:

a. Advanced Catalysts: The development of more efficient and selective catalysts that can enhance product yields while reducing by-products.

b. Carbon Capture: Implementing carbon capture technologies to reduce emissions and contribute to the fight against climate change.

c. Integration of Renewable Feedstocks: Incorporating bio-oils and other sustainable feedstocks into the FCC process to align with the growing demand for eco-friendly products.

d. Process Optimization: Continuous improvement in the overall design and operation of FCC units for increased efficiency and reduced environmental impact.

Before you go...

If you liked this topic, you might be interested in my Petroleum Refining Course.

Throughout this course, we explore a wide range of topics, including:

- Refining and Fractionation

- Atmospheric Distillation Column

- Vacuum Distillation

- Hydrotreating (Hydrogenation)

- Blending

- Reforming

- Isomerization

- Alkylation

- Steam Cracking

- Fluid Catalytic Cracking

- Gas Sweetening (Hydrodesulfurization)

- Coking

Final thoughts

In conclusion, Fluid Catalytic Crackers are pivotal in the petroleum refining industry for their ability to produce valuable fuels from heavy crude oil.

Understanding their operation, addressing environmental concerns, and embracing future trends are crucial for the industry’s sustainability.

As refineries adapt to changing demands and regulations, FCC technology will continue to evolve, ensuring a cleaner and more efficient refining process that meets the energy needs of a rapidly evolving world.

Is there anything in especial that you liked the most? or Maybe you are not quite into the new trends? Just reply to this e-mail and let me know!