Now, lets talk about: EV Batteries!

Electric vehicle (EV) batteries are of significant importance to chemical engineers due to their central role in the advancement of sustainable transportation.

Chemical engineers contribute to the development, optimization, and production of EV batteries, playing a crucial part in improving their performance, energy efficiency, and safety.

They are involved in research and development of battery materials, electrode design, electrolyte formulations, and manufacturing processes. Chemical engineers also focus on optimizing battery performance, enhancing charging capabilities, and extending battery life.

By addressing the challenges associated with EV batteries, chemical engineers are at the forefront of promoting the widespread adoption of electric vehicles, which contributes to reducing greenhouse gas emissions, enhancing energy efficiency, and creating a cleaner and more sustainable transportation sector.

So… lets check Batteries!

Subscribe to My Newsletter So You Get All the Most Relevant Monthly News

What Are the Most Common Types of Batteries Used in EV?

There are lots of batteries, most used in electronics and lots used in heavy duty tools, but have you ever wonder what are the specific batteries used in the EV industry? Lets see:

Lithium-ion Batteries:

- Lithium-ion (Li-ion) batteries are the most prevalent type of battery used in EVs today.

- They offer high energy density, allowing for longer driving ranges, and can be recharged hundreds to thousands of times.

- Within the category of lithium-ion batteries, there are different variations, such as lithium iron phosphate (LiFePO4), lithium nickel manganese cobalt oxide (NMC), and lithium nickel cobalt aluminum oxide (NCA).

Nickel-Metal Hydride (NiMH) Batteries:

- Although less common in newer EVs, NiMH batteries have been used in some earlier hybrid and electric vehicles.

- They have a lower energy density compared to lithium-ion batteries and can provide a shorter driving range.

- NiMH batteries are gradually being replaced by lithium-ion batteries due to their superior performance.

Solid-State Batteries:

- Solid-state batteries are an emerging technology that holds promise for future EVs. They use solid electrolytes instead of liquid or gel-based electrolytes found in traditional batteries.

- Solid-state batteries have the potential to offer higher energy density, faster charging times, improved safety, and longer lifespan compared to current battery technologies.

- However, they are still in the early stages of development and not widely available in commercial vehicles.

Lithium Polymer Batteries:

- Lithium polymer (LiPo) batteries are a variation of lithium-ion batteries.

- They use a solid polymer electrolyte instead of a liquid or gel electrolyte, which allows for more flexible packaging and potentially lighter weight.

- LiPo batteries have been used in some EVs and consumer electronics, but their usage is not as widespread as conventional lithium-ion batteries.

Common Challenges of EV Batteries for Chemical Engineers

The battery life of electric vehicle (EV) batteries is a critical aspect that impacts their overall performance and usability. Some of the most important challenges associated with battery life include:

Capacity Fade: Over time, the capacity of a battery to store and deliver energy gradually diminishes. This capacity fade is mainly due to chemical and physical degradation processes that occur within the battery during charge and discharge cycles. Addressing capacity fade is crucial to ensure the long-term performance and range of EVs.

Calendar Aging: Even when not in use, batteries can experience degradation over time, known as calendar aging. Factors such as temperature, state of charge, and the chemical composition of the battery can influence the rate of calendar aging. Managing calendar aging is important to extend the lifespan of batteries and maintain their performance.

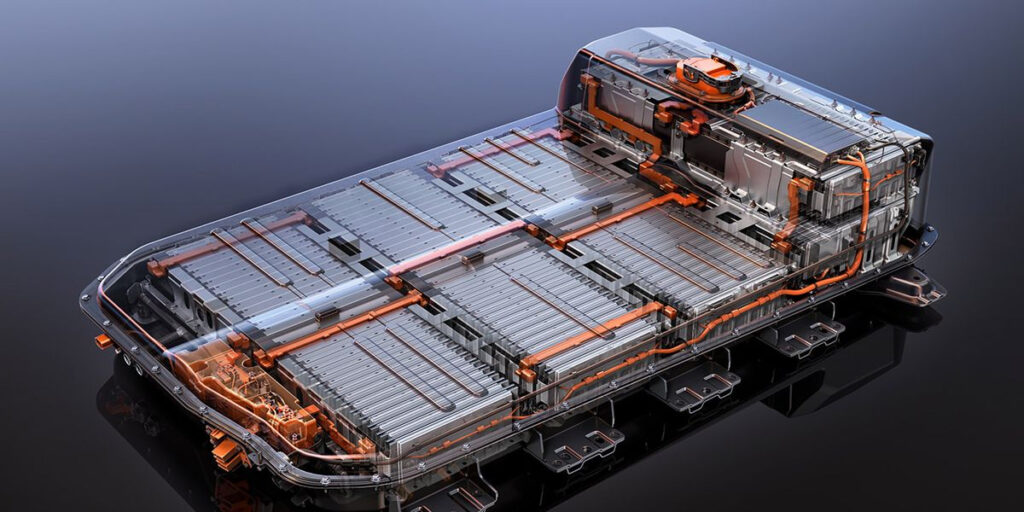

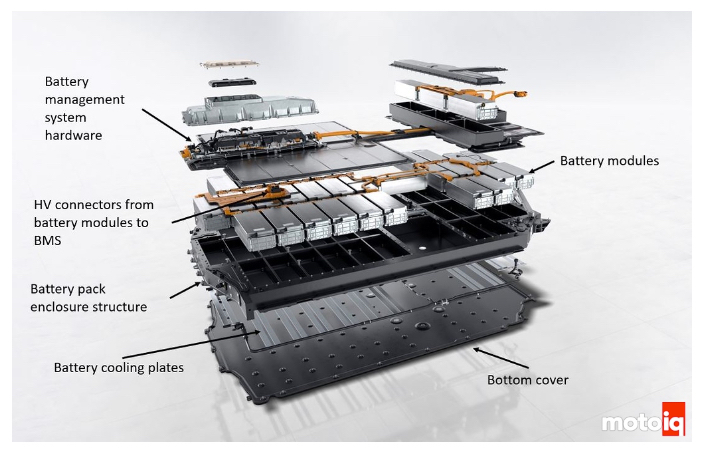

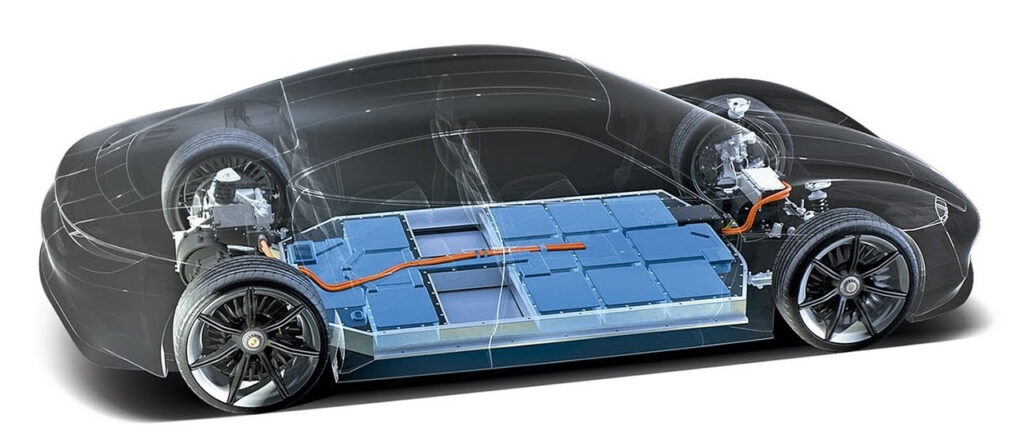

Thermal Management: High operating temperatures or large temperature variations can accelerate the degradation of battery materials and affect battery life. Efficient thermal management systems are crucial to maintaining optimal temperature conditions for the battery, preventing overheating or overcooling, and mitigating thermal-induced degradation.

Charging and Discharging Efficiency: Inefficient charging and discharging processes can impact battery life. Factors such as charging rates, depth of discharge, and charging algorithms can influence the stress experienced by the battery and affect its longevity. Optimizing charging and discharging protocols is essential to maximize battery life.

Mechanical Stress: Mechanical stress from factors like vibrations, shocks, and physical impacts can lead to the deterioration of battery components and affect their lifespan. Ensuring robust packaging and designing battery systems that can withstand various mechanical stresses are vital for enhancing battery durability.

Safety Considerations: Battery safety is of paramount importance. Uncontrolled chemical reactions, thermal runaway, or short circuits can lead to safety hazards and impact the overall battery life. Implementing safety measures and incorporating robust battery management systems are essential to protect the battery and prolong its operational life.

Addressing these challenges requires a multidisciplinary approach involving chemical engineering, materials science, electrical engineering, and other relevant fields. Ongoing research and development efforts aim to tackle these challenges and improve the longevity and reliability of EV batteries, ultimately supporting the widespread adoption of electric vehicles.

Final thoughts

In conclusion, the significance of electric vehicle (EV) batteries extends beyond the realm of engineers—it has profound implications for society as a whole. Engineers play a pivotal role in developing, optimizing, and improving EV batteries, addressing the challenges associated with their performance, efficiency, and longevity.

By advancing battery technologies, engineers contribute to a sustainable and clean transportation sector, reducing greenhouse gas emissions and combating climate change. However, several challenges lie ahead, such as capacity fade, calendar aging, thermal management, charging efficiency, mechanical stress, and safety concerns. Overcoming these challenges requires continued research, innovation, and collaboration across disciplines.

By surmounting these obstacles, engineers can enhance the reliability, durability, and safety of EV batteries, making electric vehicles more accessible, reliable, and environmentally friendly.

By driving the evolution of EV batteries, engineers play a crucial role in shaping a future with cleaner and sustainable transportation for the betterment of society and the planet.

That will be it guys! I hope you enjoyed this blog post.

Is there anything in especial that you liked the most? or Maybe you are not quite into the new trends? Let me know in the comments or via e-mail!